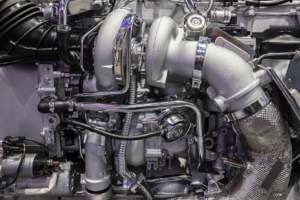

Single-Turbo Kit

Single turbochargers alone have limitless variability. Differing the compressor wheel size and turbine will lead to completely different torque characteristics. Large turbo kits will bring on high top-end power, but smaller turbos will provide better low-end grunt as they spool faster. There are also ball bearing and journal bearing single turbo kits. Ball bearings provide less friction for the compressor and turbine to spin on, thus are faster to spool (while adding cost).

Advantages of the Single-Turbo kit

- Cost effective way of increasing an engine’s power and efficiency.

- Simple, generally the easiest of the turbocharging options to install.

- Allows for using smaller engines to produce the same power as larger naturally-aspirated engines, which can often remove weight.

Disadvantages of the Single-Turbo kit

- Single turbos tend to have a fairly narrow effective RPM range. This makes sizing an issue, as you’ll have to choose between good low-end torque or better high-end power.

- Turbo response may not be as quick as alternative turbo setups.

Twin-Turbo Kit

Just like single turbochargers, there are plenty of options when using two turbochargers. You could have a single turbocharger for each cylinder bank (V6, V8, etc). Alternatively, a single turbocharger could be used for low RPM and bypass to a larger turbocharger for high RPM (I4, I6, etc). You could even have two similarly sized turbos where one is used at low RPM and both are used at higher RPM. On the BMW X5 M and X6 M, twin-scroll turbo kits are used, one on each side of the V8.

Advantages of the Twin Turbo kit

- For parallel twin turbo kits on ‘V’ shaped engines, the benefits (and drawbacks) are very similar to single turbo setups.

- For sequential turbos or using one turbo at low RPM and both at high RPM, this allows for a much wider, flatter torque curve. Better low-end torque, but the power won’t taper at high RPM like with a small single turbo.

Disadvantages of the Twin Turbo kit

- Cost and complexity, as you’ve nearly doubled the turbo components.

- There are lighter, more efficient ways of achieving similar results (as discussed below)

Twin-Scroll Turbo Kit

Twin-scroll turbochargers are better in nearly every way than single-scroll turbos. By using two scrolls, the exhaust pulses are divided. For example, on four-cylinder engines (firing order 1-3-4-2), cylinders 1 and 4 might feed to one scroll of the turbo, while cylinders 2 and 3 feed to a separate scroll. Why is this beneficial? Let’s say cylinder 1 is ending its power stroke as the piston approaches bottom dead center, and the exhaust valve starts to open. While this is happening, cylinder 2 is ending the exhaust stroke, closing the exhaust valve and opening the intake valve, but there is some overlap. In a traditional single-scroll turbo manifold, the exhaust pressure from cylinder 1 will interfere with cylinder 2 pulling in fresh air since both exhaust valves are temporarily open, reducing how much pressure reaches the turbo and interfering with how much air cylinder 2 pulls in. By dividing the scrolls, this problem is eliminated.

Advantages of the Twin-Scroll Turbo kit

- More energy is sent to the exhaust turbine, meaning more power.

- A wider RPM range of effective boost is possible based on the different scroll designs.

- More valve overlap is possible without hampering exhaust scavenging, meaning more tuning flexibility.

Disadvantages of the Twin-Scroll Turbo kit

- Requires a specific engine layout and exhaust design (e.g: I4 and V8 where 2 cylinders can be fed to each scroll of the turbo, at even intervals).

- Cost and complexity versus traditional single turbos.