If you notice a significant reduction in your boost, or grayish-blue fumes coming out from your exhaust pipe, chances are that you may be experiencing turbo failure. This brings us to the commonly-asked question – Why do turbochargers fail?

It can be incredibly frustrating to step on the pedal expecting an incredible burst of speed only to experience something far less satisfactory.

In this article, we will explore the answers to the question – why do turbochargers fail? In greater detail. We will be covering a wide range of topics, including how to identify the early signs of a failing turbo, the causes behind turbo failure, and what you can do to protect your engine.

How Do Turbochargers Work?

A turbocharger is a separate induction system installed by car makers to boost engine power. Adding a turbo enables small cars to achieve the performance of bigger cars with larger engines.

Most car manufacturers are now adding turbochargers to their line-up as it allows them to provide a smaller engine that delivers the power-packed performance of a bigger one while taking up less space and improving fuel efficiency.

Here’s How It Works

- A car engine generates the power to propel a car’s wheels by mixing air and fuel before combustion.

- A turbocharger utilizes the exhaust fumes produced during this process to spin its air pump or compressor, pushing more air into the engine chambers for increased power production.

- The increase in horsepower provides a turbo boost that accelerates your car forward, enabling it to achieve far greater speeds.

However, any damage to the engine or its air pump can result in a diminished boost or delay in picking speed.

So, why do turbochargers fail? Let’s find out more below.

What are the Signs of a Failing Turbo?

Sure signs and symptoms can indicate problems with your turbo engine or a blown turbocharger:

-

Poor Performance

If your car doesn’t accelerate as powerfully as before or if you experience a significant delay in reaction to your input, you likely have a malfunctioning device.

At the same time, a turbocharged vehicle unable to achieve high speeds or reach the velocities it did earlier may also be on the brink of failure.

-

A Whining Sound

While a turbocharger’s primary purpose is to boost your vehicle’s speed, a bonus is that it also muffles engine noise.

So, if you hear a loud, whining noise from your engine, similar to a police siren or a dentist’s drill, it can be an early sign of turbo failure.

If the fault is allowed to continue unchecked, the noise will worsen and become shriller. The best course of action is to have a mechanic look at your turbo and engine as soon as you detect a faint whining noise.

-

Exhaust Smoke

An oil leak from a cracked turbo housing or damaged internal seals can also cause turbo failure. As the leaked oil burns off, it produces a bluish-green smoke that is very hard to miss.

If you see discolored fumes, especially once the engine revs increase shortly after idling, you may have a failing turbo.

-

Check Engine Light

As we learned from Sheldon in The Big Bang Theory, it’s never wise to ignore a check engine light. The entire purpose of adding the light to your dashboard is to apprise you of any engine problems early on.

So, it’s crucial to check your car out as soon you notice the check engine light is on.

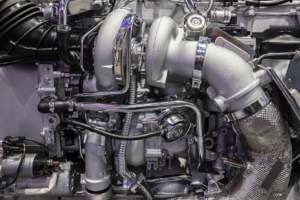

Why Do Turbochargers Fail?

Now that you are familiar with the signs of turbo failure, let’s explore the reasons behind the same:

Oil Contamination

Dirty or contaminated oil damages the bearings, causing faster wear-and-tear, leading to turbo failure. Let’s take at the causes and how to prevent them.

Here are the primary factors that cause oil contamination:

- A filthy or broken oil filter.

- Even fresh oil can be contaminated by high carbon buildup in the engine.

- New oil can also get contaminated accidentally during servicing.

- Engine damage or wear can leave behind particles in the oil.

- A malfunctioning oil filter bypass valve eventually causes fluid contamination.

- Oil degradation due to long service intervals or extremely high temperatures.

Tips for Preventing Turbo Failure from Contaminated Oil

- When installing a new turbo, follow the manufacturer’s recommendations and always use fresh oil and a new oil filter.

- Ensure the engine is running on the proper oil.

- Ensure the oil input pipes are cleaned or changed regularly to eliminate any sludge or carbon buildup that can get into the turbo.

Impact Damage

Turbo failure is also caused by foreign objects entering the turbine or compressor if they get pulled into the air intake.

Here are the Primary Reasons for Impact Damage –

- A poor quality or damaged filter can cause foreign articles to enter the air intake.

- Damaged hoses can also allow small particles to enter the air intake.

- If the gasket material enters the intake.

- In case items like nuts, bolts, washers, etc., are left in the intake pipe during servicing.

- Broken engine parts, such as broken piston fragments, injector nozzles, or valves, also cause damage upon entering the air intake.

- Any particles left from a previously failed turbocharger.

Tips for Avoiding Impact Damage –

- Ensure all airlines are in good shape and unblocked.

- To guarantee a flawless seal, always swap old gaskets with new ones.

- Replace the old air filter with a new one after disposing of the old one.

- Before installing the replacement, ensure no turbo or engine particles are still in the system from the prior failure.

Oil Leaks

Oil leaks at the compressor and turbine end or both are a significant reason turbochargers fail.

Here are the Common Reasons behind Oil Leaks at the Compressor/Turbo End

- An air intake filter that is blocked (compressor).

- An air intake hose or pipe blocked or damaged (compressor).

- Either an intercooler leak or a potential air leak on the intake hoses (compressor).

- A leakage in the exhaust or EGR system (turbine).

- The oil drainpipe from the turbo to the engine may become blocked (turbine and compressor).

- A blockage in the engine breather (compressor and turbine).

- Any damage to the rotating components of the turbo and excessive bearing clearance can also cause oil leaks at the compressor and turbo end.

- You can also experience oil leaks if your engine is fitted with an incorrect turbocharger (compressor and turbine).

How to Deter Oil Leaks to Prevent Turbo Failure:

- Regularly check for debris/blockages in the air and oil drain systems.

- Make sure there are no spills or leaks in the exhaust system.

Oil Starvation

Restrictions or blockages in the engine oil supply, even for a few seconds during a high-speed operation, can result in shaft seizure or micro-welding, leading to turbo failure.

Here are the Primary Causes of Oil Starvation.

- Carbon build-up in the oil feed pipe or low oil levels in the slump.

- Blockage caused due to a bent oil feed pipe.

- A damaged/blocked oil filter or pump.

- Fitting an incorrect oil inlet gasket or applying silicone to the gasket can also restrict supply.

- Not priming the replacement turbo using oil while fitting.

Prevent Turbo Failure Caused by Oil Starvation

- Avoid using silicone in oil gaskets as it detaches easily and causes blockages.

- Clean and replace the oil inlet pipes frequently to clear out carbon deposits or sludge that can restrict the oil supply to the bearings.

- Keep checking the oil pressure and oil supply to the turbo.

- Always use new oil filters and oil when fitting a new turbo. Go for products that the vehicle manufacturer recommends.

Overspeeding

Overspeeding refers to a situation in which the turbo rotates at a far greater speed than prescribed operational limits. In such cases, turbo failure is caused by damage to the turbine or the compressor bearings and wheels.

Here is a List of Factors That Lead to Overspeeding –

- Any blockage in the air intake filter can damage or even split the air hose, allowing more air to enter the turbo.

- A “chipped” engine with a modified onboard computer that is not in line with standard specifications can also result in overspeeding.

- A tampered waste gate or damaged and worn injectors can push the turbo beyond its limits.

- An incorrect turbo fitting or signal loss to the SREA (Simple Rotary Electronic Actuator) for the wastegate or VNT control also results in overspeeding.

How to Avoid Turbo Failure from Overspeeding

- Periodically check for any leaks or blockages in the air intake.

- Check that the VNT linkage and wastegate are working properly.

- Ensure that the ECU and electronic sensors are functioning correctly.

Why Do Turbochargers Fail? Frequently-Asked Questions

-

How do you stop a turbo from failing?

Ans. You can avoid turbo failure through regular maintenance and timely oil changes. It’s also essential to use the correct and good-quality engine oil. Also, a gentle turbo startup can prolong the life of your turbocharger.

-

Can a turbo fail suddenly?

Ans. A turbo is usually designed to last as long as a car does. However, improper maintenance can lead to blockages accompanied by rapid wear-and-tear that damages the turbo components over time.

The 3 leading turbo killers are oil contamination, starvation, and damage caused by foreign particles.

-

Can a failing turbo be repaired?

Ans. Yes, a turbo can be repaired at a good turbo repair center like Diesel Components Inc., a regional warehouse distributor and authorized repair facility of turbochargers for Garrett AiResearch, Garrett Turbo, and Schwitzer, among others.

Seeking Turbocharger Repair Services? Contact Diesel Components Inc., Today!

We hope that we can answer all queries regarding– why turbochargers fail.

If you are experiencing any of the symptoms of turbo failure outlined above and are looking for an experienced turbocharger repair center, drive down to Diesel Components Inc. today!

As a family-owned, regional warehouse distributor and certified turbocharger repair center, DCI uses top-quality parts and the latest repair techniques to offer the best turbocharger repair services in Burnsville and surrounding areas.

Whether you need new parts, including a manifold gasket, air discharge hose, or clamp, or are looking for more complex services like wheel balancing, our experts have you covered.

We also exchange new or rebuilt turbochargers and have extensive in-house rebuilding capabilities that provide a fast turnaround on your turbocharger. If your diesel engine has a turbocharger problem, we’ll know how to fix it, regardless of how you use it.

If you want to learn more about how we can fix your failing turbocharger, please do not hesitate to contact us today!